- August 4, 2021

- A2K WordPress

- 0

Paying Attention To Detail

- Evelin Arteaga Roman – Project Engineer (BIM/VDC))

- August 04, 2021

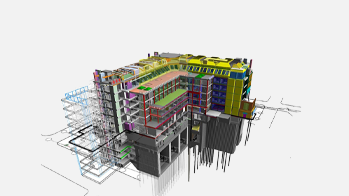

Through the years, I have seen the BIM construction industry move towards the prefabrication process. It has profoundly influenced BIM and the way we think of construction. As construction advances into this process, we are looking more and more into software Add-Ins that are compatible with manufacturing tools. In recent projects I have worked on, I have experienced the level of detail needed to execute this process successfully. It is crucial now more than ever to be precise in modeling for its accuracy to translate and transfer data into prefabrication.

Throughout my career, I have worked on projects that have consisted of prefabricating electrical devices and conduits. In one of these recent projects, I had the opportunity to use Greenlee Bendworks™ . Greenlee Bendworks™ is a Revit Add-In that allows BIM modelers/detailers to use its templates and tools. While working on this project, Greenlee Bendworks™ introduced me to Revit families that have built-in parameters in their conduits. As a BIM modeler, this was a crucial step into our modeling process because each conduit had certain criteria for it to be identifiable at the end of the BIM process. At this stage, we had to be prepared to include: Conduit ID, System Type, and Voltage. Once the conduit run and its parameters were complete, then the rest of our BIM team used the Greenlee Bendworks™ tool called Splitting to allow the conduit to split into increments of 10′. Greenlee Bendworks™ then automatically populated a coupling every 10′. In doing so, these areas of the conduit would eventually be cut and prefabricated in real time. Up until now, it really became crucial to have the entire conduit run have the correct information, the correct amount of bend angles, and the correct conduit lengths for it to be ready for transfer data.

To quality assure and quality control, filters and schedules played a big part in our BIM process. In this project, the lack of color in the conduit would indicate to us that the conduit run did not have the conduit information throughout the run. In our schedules, one of the columns would indicate what bend angles were not standard, and lastly what conduits were less than 4’.

As the BIM portion of the prefabrication process neared its end, an output file would eventually have been created for the electricians to follow. This information gets transcribed into text, allowing electricians to use Greenlee tools effectively offsite and get it ready to get transferred to the construction site. Overall, I found this process to be an effective way to translate information near to perfection.

My experience with Greenlee Bendworks™ has been great because it is user-friendly and efficient. I am excited for Add-Ins like these to succeed and advance because prefabrication is becoming increasingly relevant in the BIM industry. This is ultimately a great way to produce work efficiently and successfully. I am excited for the prefabrication construction and BIM advances.